SPECIAL TECHNOLOGIES

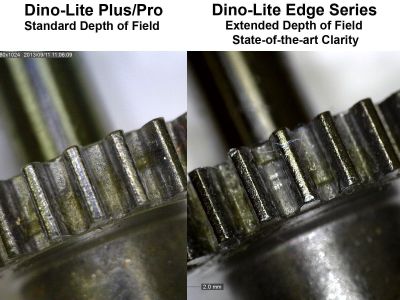

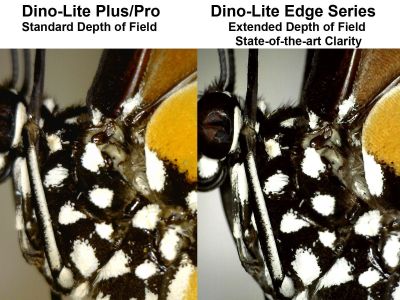

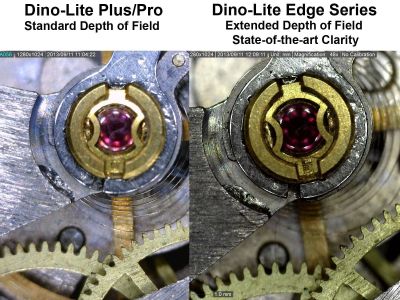

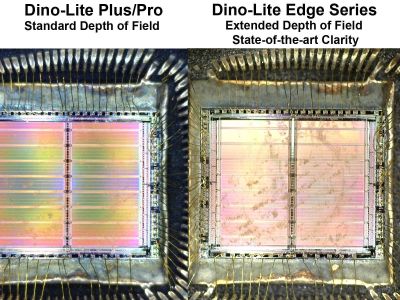

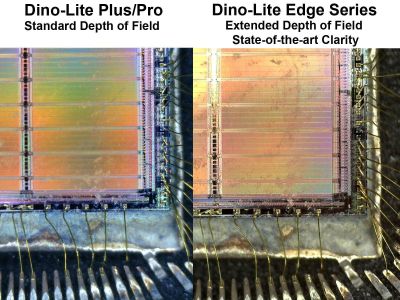

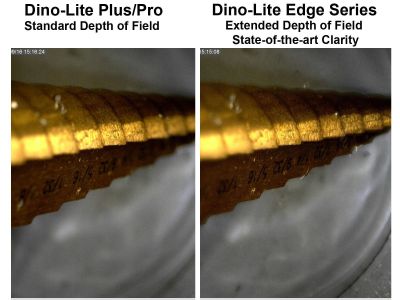

EDOF (Extended Depth of Field)

Extended Depth of Field, also known as focus stacking, is a digital image processing technique which combines multiple images taken at different focus distances to give a resulting image with a greater depth of field (DOF) than any of the individual source images.

Focus stacking can be used in any situation where individual images have a very shallow depth of field.’ (source: Wikipedia)‘Extended Depth of Field, also known as focus stacking, is a digital image processing technique which combines multiple images taken at different focus distances to give a resulting image with a greater depth of field (DOF) than any of the individual source images. Focus stacking can be used in any situation where individual images have a very shallow depth of field.’ (source: Wikipedia)

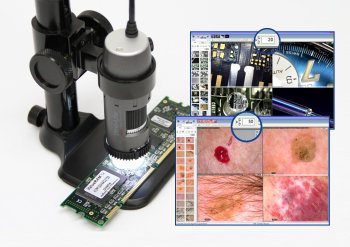

Some Dino-Lite models offer this special technique, the EDOF capture mode can take several pictures at different levels of focus and stack them into a clear image automatically with 1 click of the mouse. The EDOF images maintain the picture quality from its original pictures and can be stored and viewed in the DinoCapture 2.0 software. All AM4025X, AM48xx, AM49xx, AM7025X, AM79xx and AM739xx models include EDOF technology.

(*At the moment EDOF only functions under Windows OS)

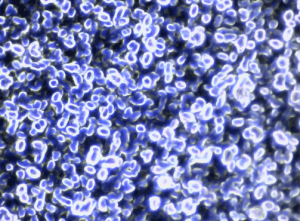

With EDOF

Without EDOF

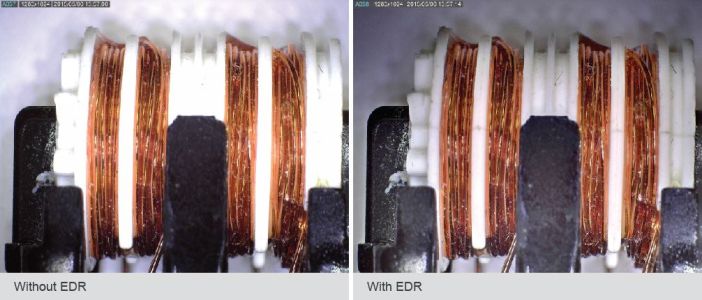

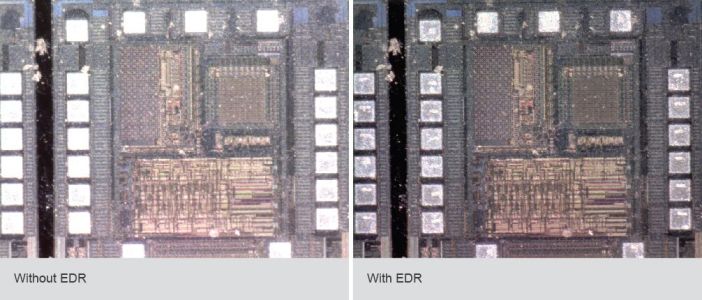

EDR (Extended Dynamic Range)

EDR is a set of techniques used in imaging and photography to reproduce a greater dynamic range of luminosity than possible using standard digital imaging or photographic techniques.

EDR images can represent a greater range of luminance levels found in real-world scenes, from direct sunlight to faint nebula. It is often achieved by capturing and then combining different exposures of the same subject matter (source: Wikipedia). EDR (Extended Dynamic Range) is an image processing tool exclusive to some of the Dino-Lite Edge models (DinoCapture 2.0 version 1.4.8 and higher). For surfaces with large variation in brightness, the EDR capture tool can be ideal for capturing a more neutral image of the surface by only a few clicks. The EDR capture mode takes 3 pictures at different exposure levels (standard, underexposed and overexposed) and stacks them into a clear image automatically with 1 click of the mouse. The EDR images can be stored and viewed in the DinoCapture 2.0 software.

With EDR

Without EDR

AMR (Automatic Magnification Reading)

The AMR function automatically detects and displays the magnification of the Dino-Lite. The magnification is displayed within the Dino-Lite software and stored with the captured picture.

The AMR function simplifies the measuring process and improves the accuracy of the measurement. AMR is recommended when high precision and/or calibrated (calibration is done manually) measurements need to be made.

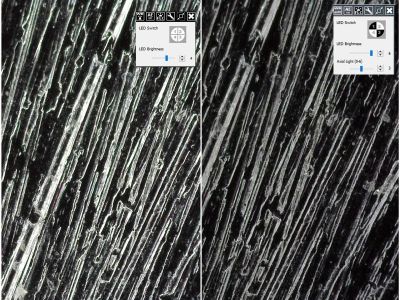

FLC (Flexible LED Control)

With the Flexible LED Control (FLC) function the Dino-Lite LED’s can be controlled and adjusted.

The LED’s on the Dino-Lite models with the FLC function are divided in 4 different quadrants which can be adjusted separately. 6 levels of illumination can be chosen. The FLC function is useful when objects need to be illuminated from the side or when certain parts of the object need more or less light.

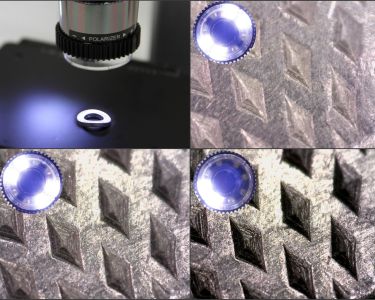

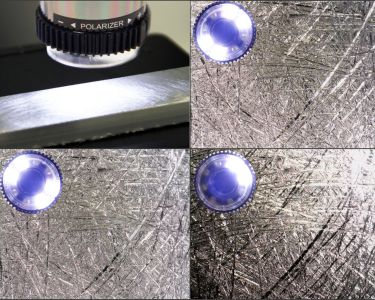

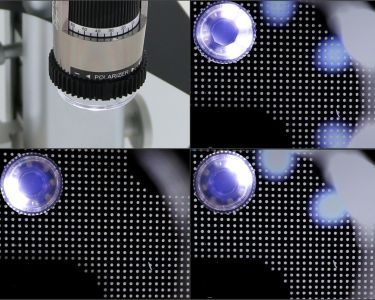

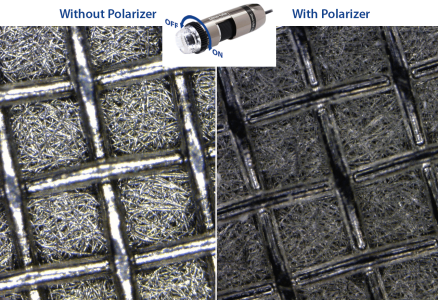

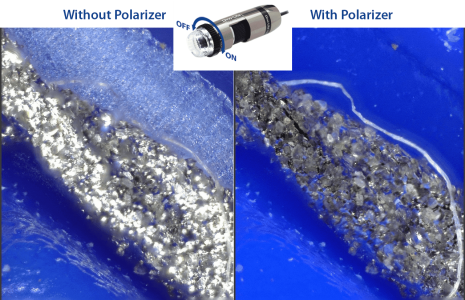

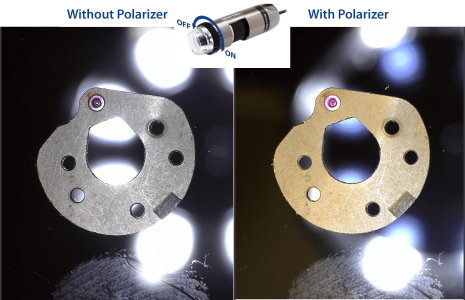

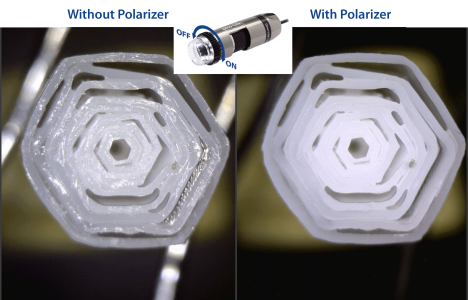

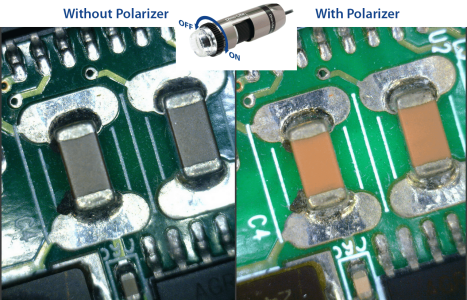

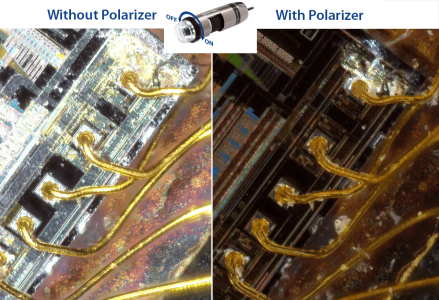

Polarizing filter/ polarizer

Many Dino-Lite models offer a built-in polarizing filter.

A polarizer is an optical filter that polarizes the light passing through it, which is used for reducing reflections on shiny objects and for improving contrast. The Dino-Lite polarizer can be switched on/off or can be adjusted to offer full or half polarization.

A polarizer filter is highly recommended when working with shiny or reflective objects such as metal, plastic, glass, jewelry or electronics, but also for use in dermatology for skin or scalp check.

With Polarizer

Without Polarizer

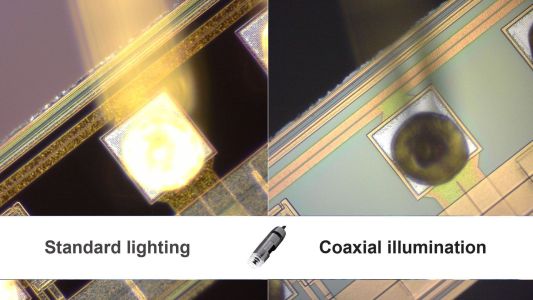

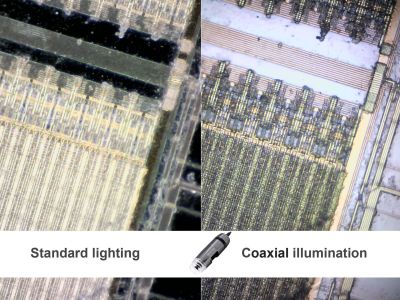

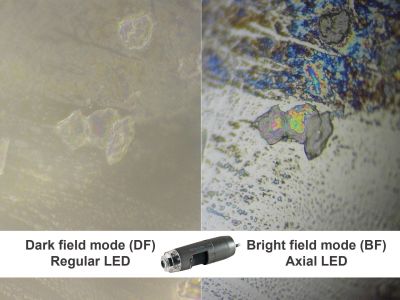

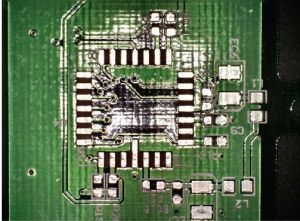

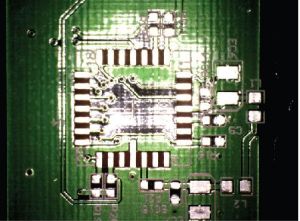

Co-axial lightning

With Coaxial Illumination the light is on the axis of the optical path and is therefore only illuminating the part of the sample that is also seen by the microscope.

Inside the Dino-Lite co-axial models there is an LED built-in on the side. This LED shines its light onto a mirror which acts like a beam splitter that projects the light directly onto the sample and also allows the image that is formed to be returned straight up to the Edge sensor. The most commonly used application for Coaxial illumination in the semiconductor industry is the quality control and inspection wafer plates. With standard brightfield illumination the structures and overlaying structures are not all visible, while with coaxial illumination these details will appear.

Other applications are the inspection of polished and chemically treated metal surfaces, inspection of microchips, microelectronics and many other surfaces that appear flat or without contrast when using brightfield illumination.

Standard lighting

Co-axial illumination