Application story Michelin

Michelin to improve quality control with a microscopic view

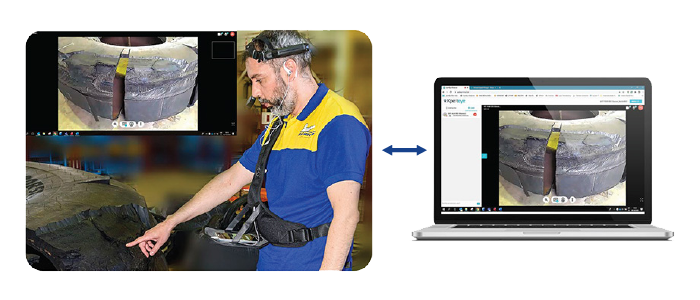

Michelin’s customer service department carries out inspections and controls in the tire production sites to provide feedback internally to other Michelin sites and externally to the subcontractors of molds and metal parts and guide them in their technical choices.

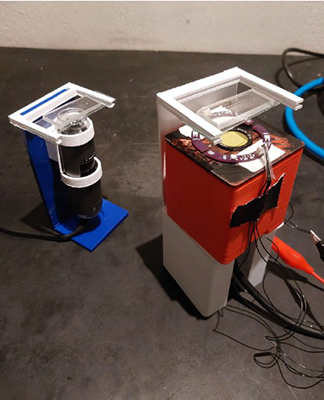

To efficiently perform these inspections, the team needs microscopes that are:

- Robust, compact, and with a long product life cycle

- Able to clearly show and highlight any defect, ideally with a polarizing camera to avoid reverberation or adding light

- High image quality with a wide range of magnification to allow precise diagnosis

- Easy to use and connected to a smartphone with a remote collaboration solution to accelerate decision making

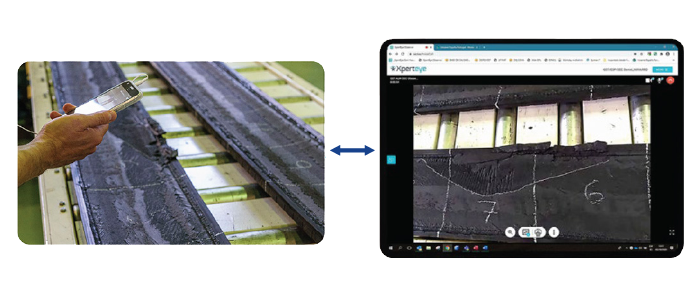

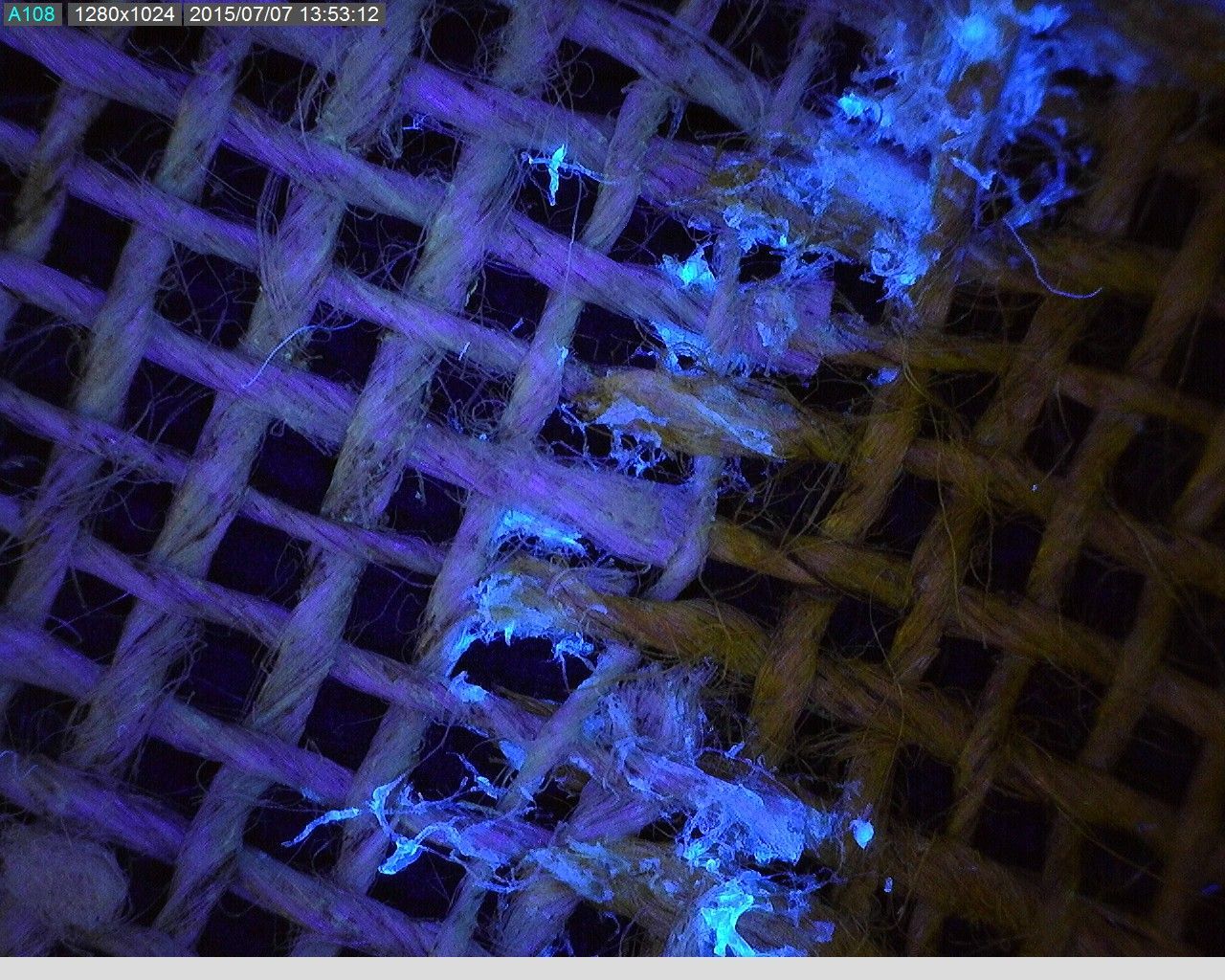

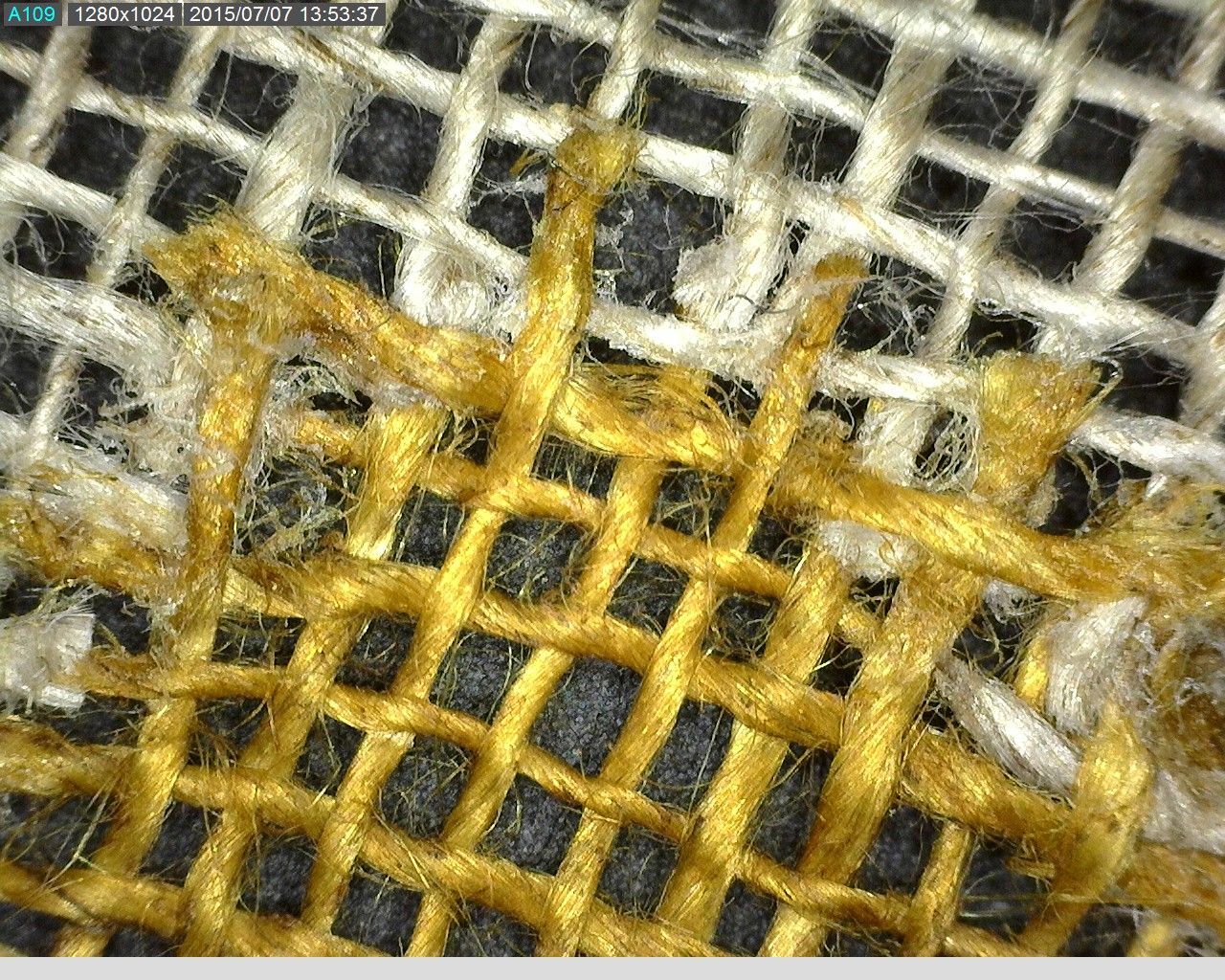

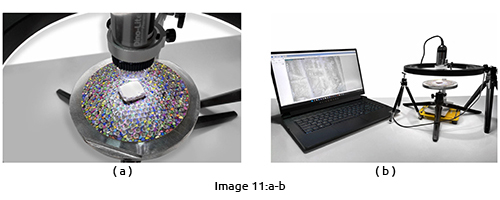

Use case: Quality control of the cleaning tools that allow the production of tires

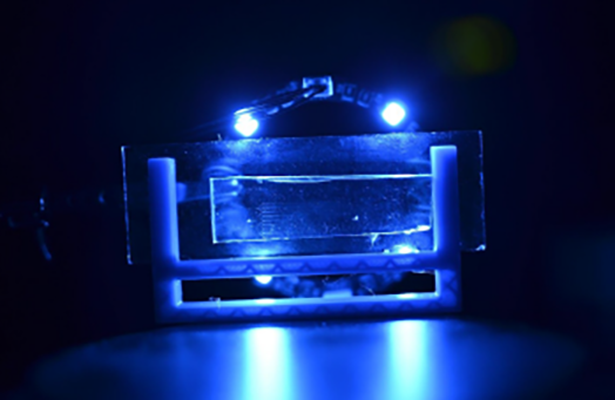

The Dino-Lite microscope is used to investigate the quality of the cleaning. By magnifying, and thanks to the excellent image quality, it is possible to see if there is still some dirt residue left. By connecting the microscope to a smartphone,

this information can be shared live for further examination.

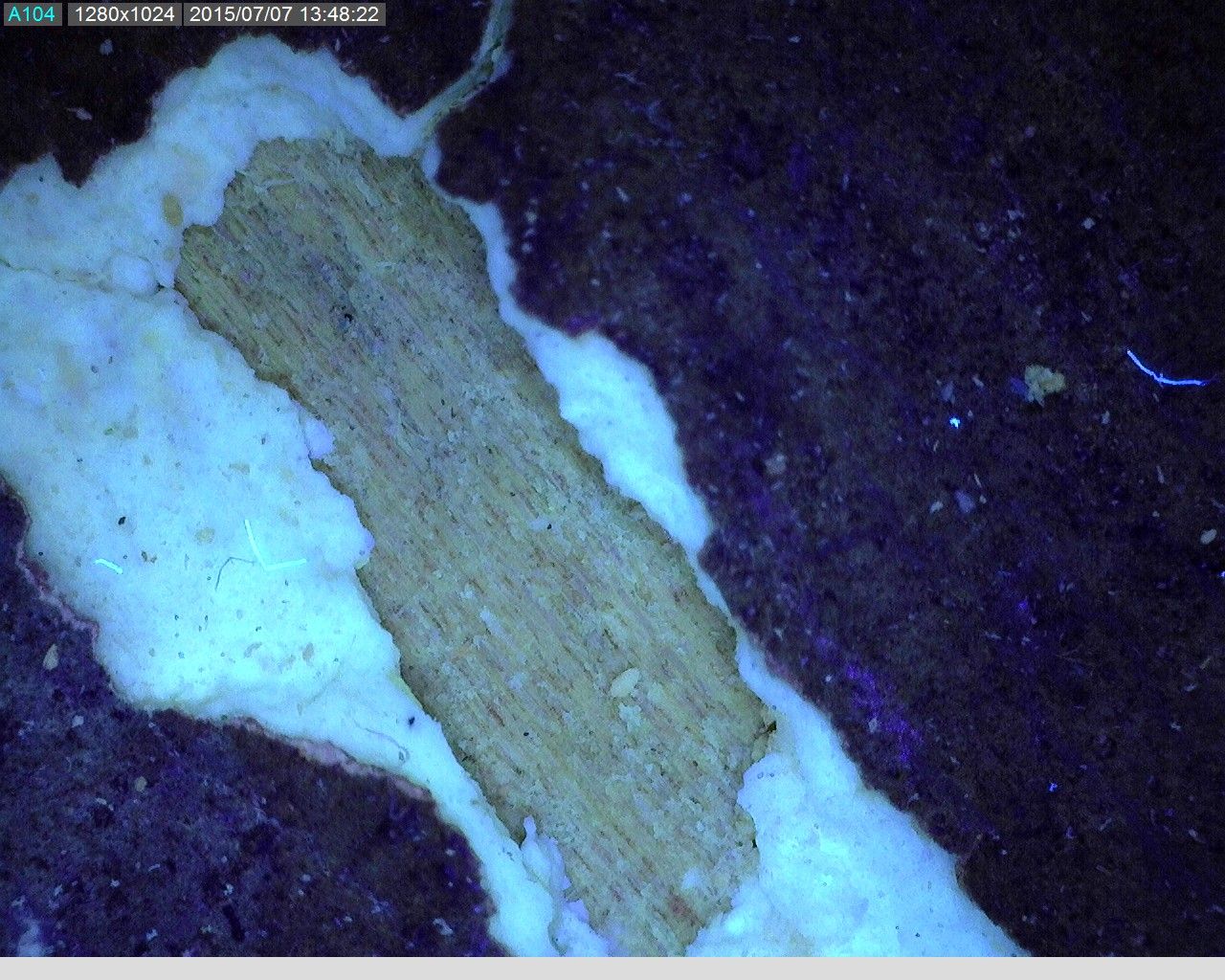

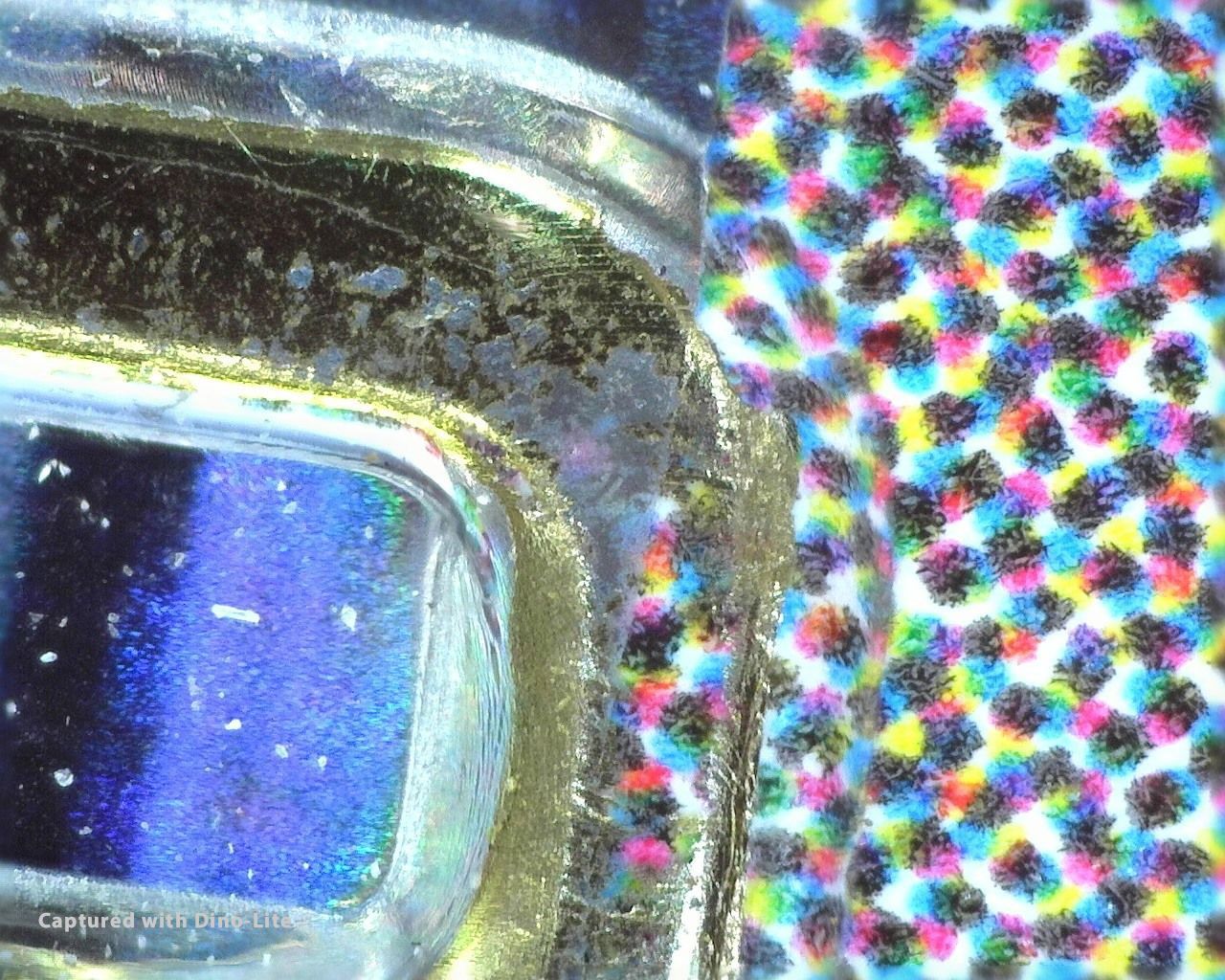

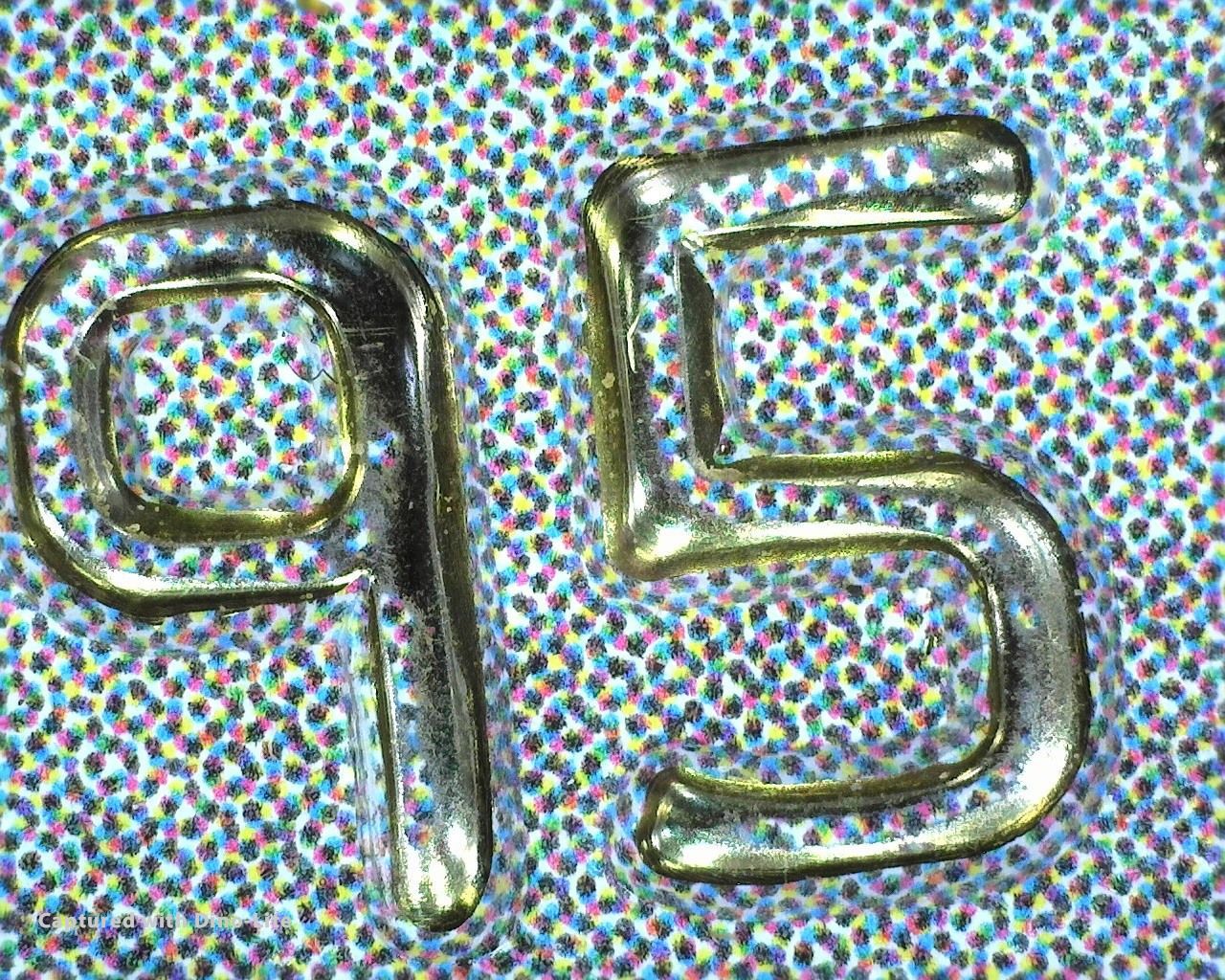

Use case: Quality control of laser marking

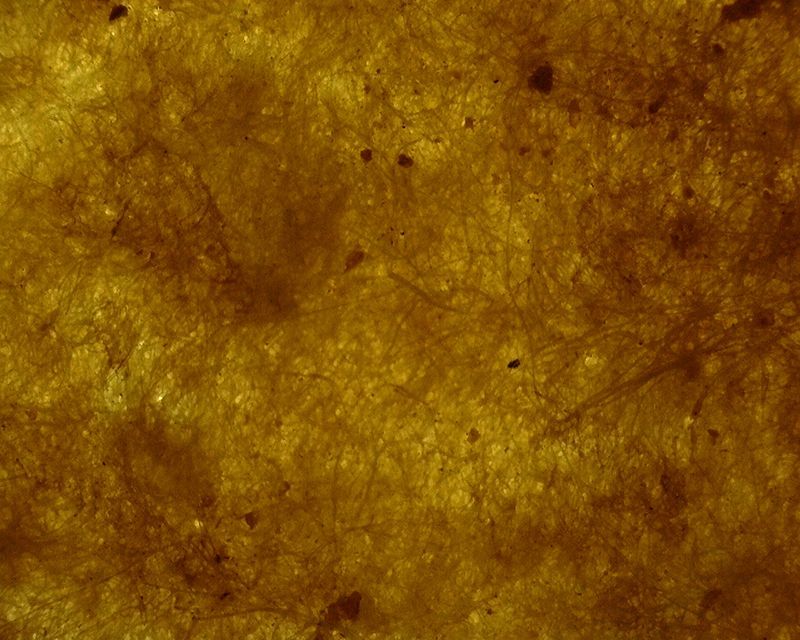

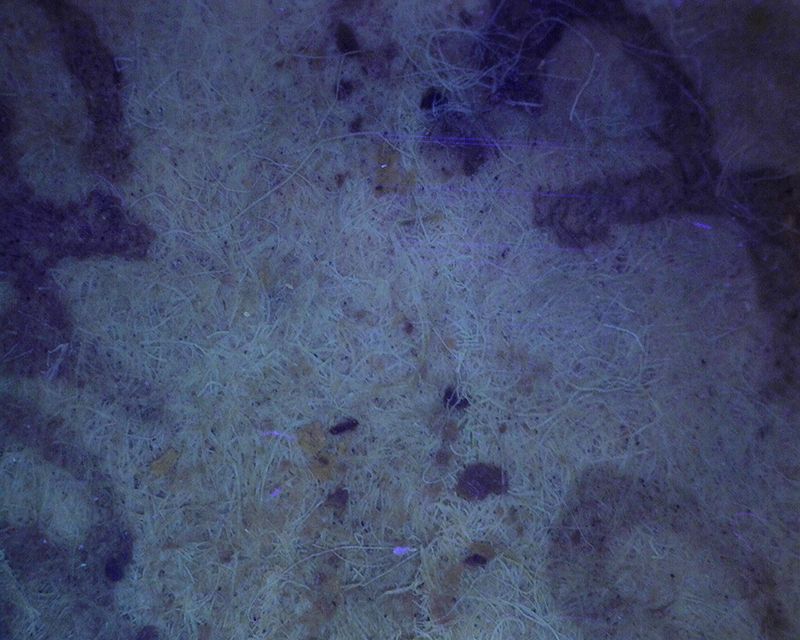

Michelin uses laser engravings on its molds. To the naked eye, only a black aspect can be seen on the mold, but when taking a closer look with a Dino-Lite microscope, the texture made by the laser can be distinguished and their cleanliness can be evaluated. The microscope shows for instance that there has been a deposit of dirt inside the texture which obstructs it and hence impacts the quality of the mold. These analyses are very easy and quick to perform and reveal very precise information.

Benefit: Produce a good tire on the first try

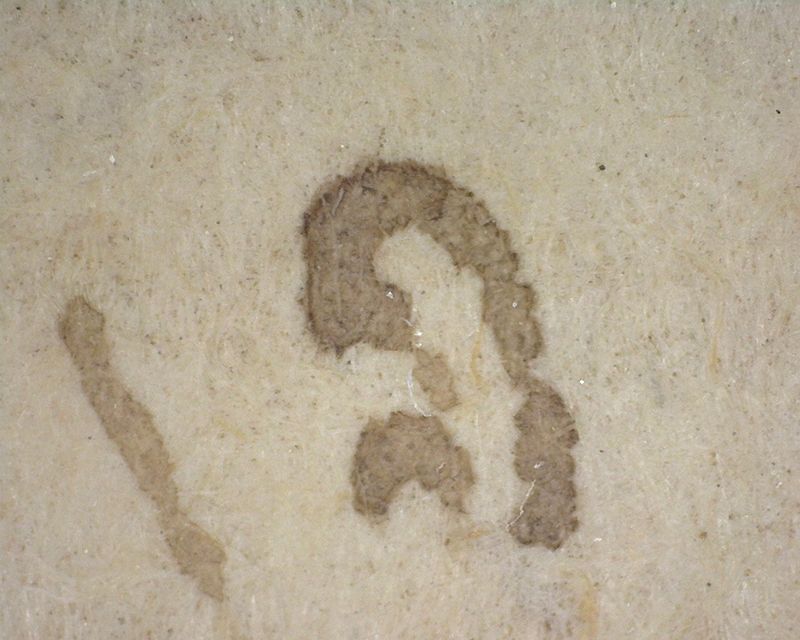

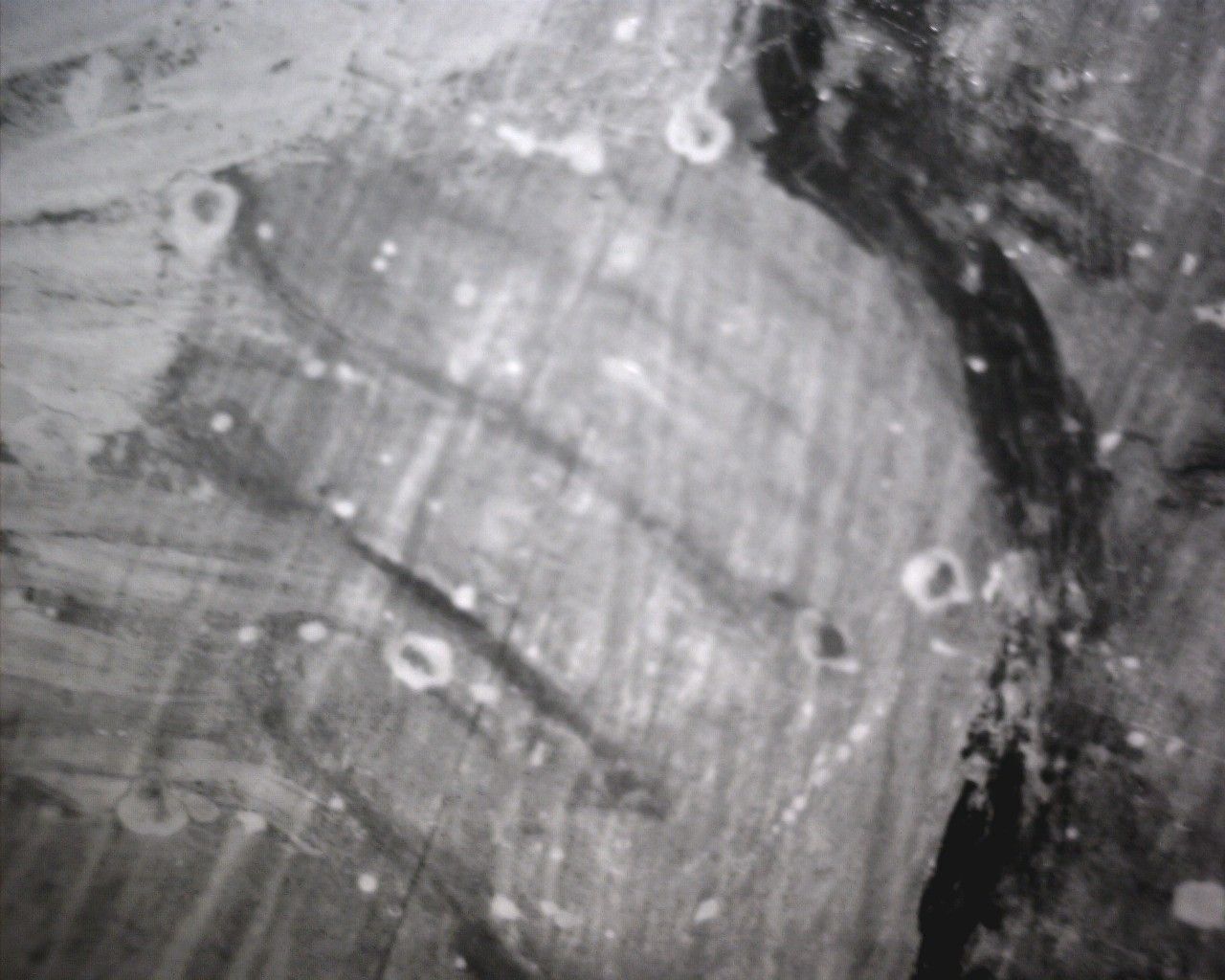

Use case: Inspection of the tire envelope

Benefits:

- Timesaving: faster decision making

- More accurate feedback to tire developers

- Reduction of customer travel

MORE APPLICATION STORIES